Setsunan University

Welcome

Laboratory for Intelligent Systems, led by Professor Haruhiko Suwa, is a part of the Department of Mechanical Engineering at Setsunan University. At our laboratory, we strive for a genuinely earth-friendly manufacturing process and its decision-making mechanism. The scope of our research includes energy-efficient manufacturing systems, manufacturing intelligence, machinability of sintered carbide tools, stability-directed planning, and proactive/reactive scheduling.

Current Research

Energy Efficient Manufacturing Systems

Energy awareness has been recognized as critical in the industry to pursue sustainable manufacturing along with the reduction of CO2 emissions and energy costs. In addition to the development of energy-saving solutions by both the top-down approach like factory energy management systems (FEMS) and the bottom-up approach associated with eco-suited machining technologies, the need for much smarter and highly-automated manufacturing systems have been increased, therefore energy-awareness, not in manufacturing processes but energy-conscious planning must be considered. We focus on developing smart ways of energy-aware manufacturing systems operations.

Energy awareness has been recognized as critical in the industry to pursue sustainable manufacturing along with the reduction of CO2 emissions and energy costs. In addition to the development of energy-saving solutions by both the top-down approach like factory energy management systems (FEMS) and the bottom-up approach associated with eco-suited machining technologies, the need for much smarter and highly-automated manufacturing systems have been increased, therefore energy-awareness, not in manufacturing processes but energy-conscious planning must be considered. We focus on developing smart ways of energy-aware manufacturing systems operations.

- Manufacturing operations based on energy load planning

- Energy-efficient optimization of tool paths

- Prediction of power consumption and energy loss

- Yonemoto, R. and Suwa, H., Task Scheduling of Material-Handling Manipulator for Enhancing Energy Efficiency in Flow-Type FMS, International Journal of Automation Technology, Vol.14 No.6, 943-950 (2020). doi.org/10.20965/ijat.2020.p0951

- Samukawa, T., Shimomoto, K., and Suwa, H., Estimation of In-Process Power Consumption in Face Milling by Specific Energy Consumption Model, International Journal of Automation Technology, Vol.14 No.6, 951-958 (2020). doi.org/10.20965/ijat.2020.p0951

- Yonemoto, R. and Suwa, H. (2019) Evaluation of Energy Efficiency and Productivity in Scheduling by Using Physical Simulator, Transactions of the Institute of Systems, Control and Information Engineers, Vol.32, No.5, pp.185-191. doi.org/10.5687/iscie.32.185

- Samukawa, T. and Suwa, H. (2016) An optimization of energy-efficiency in machining manufacturing systems based on a framework of multi-mode RCPSP, International Journal of Automation Technology, Vol.10, No.6, pp.985-992. doi.org/10.20965/ijat.2020.p0951

- Suwa, H. and Samukawa, T., A New Framework of Energy-Efficient Manufacturing Systems Based on Energy Load Profiles, Procedia CIRP, Vol.41, pp.313-317, 2016. doi:10.1016/j.procir.2015.10.011

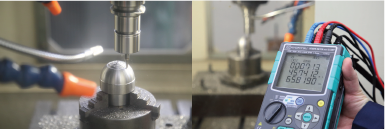

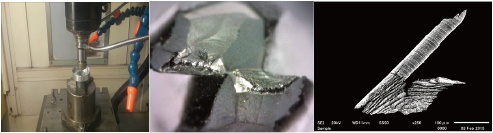

Eco Machining of Sintered Tungsten Carbide

This is a collaborative work with Prof. Moriwaki and DIJET Industrial.

Tungsten Carbide has extremely high hardness and wear-resistivity, which is expected to be applied widely to dies and molds in the near future. We are focusing on developing an efficient machining method for Tungsten Carbide, and examining the machinability and some properties of CBN tools and diamond-coated carbide cutting tools.

This is a collaborative work with Prof. Moriwaki and DIJET Industrial.

Tungsten Carbide has extremely high hardness and wear-resistivity, which is expected to be applied widely to dies and molds in the near future. We are focusing on developing an efficient machining method for Tungsten Carbide, and examining the machinability and some properties of CBN tools and diamond-coated carbide cutting tools.

- Machinability of Sintered Tungsten Carbide Tools in Milling Process

- Suwa, H., Sakamoto, S., Nagata, M., Tezuka, K., and Samukawa, T., Applicability of Diamond Coated Tools for Ball-End Milling of Sintered Tungsten Carbide, International Journal of Automation Technology, Vol.14, No.1, pp.18-25 (2020). doi: 10.20965/ijat.2020.p0018

- Samukawa, T., Shiramizu, K. and Suwa, H., Surface Properties of Sintered Tungsten Carbide with Ultra-Fine Grains in Cutting by Diamond-Coated Ball-End Tools, Proc. of the 18th International Conference on Precision Engineering (2020).

- Suwa, H., Sakamoto, S. and Samukawa, T. (2018) Capability of Diamond Coated Ball-End Tools in Milling of Sintered Tungsten Carbide, Proc. of 17th International Conference on Precision Engineering.

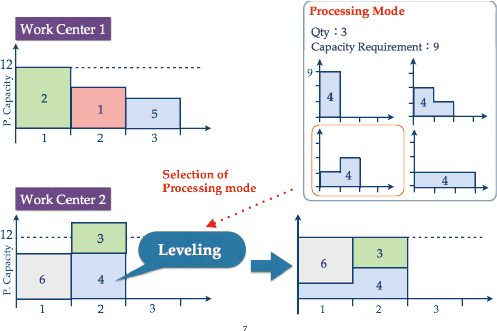

Stability Directed Planning against Uncertainties

This collaborative work with Dr. Morita at Takachiho University proposes a new framework for a stability-based decision-making process in planning and scheduling, including building a mathematical model and the development of efficient/high-speed methods while considering practical applications. The term "stability" refers to the higher predictability of a released plan/schedule and also signifies the robustness of the plan/schedule against internal and external uncertainties. In the past few years, we have focused on the application of our idea to capacity requirement planning (CRP) in the industry and proposed a robust CRP method that we believe can generate a stable load plan against dynamic changes in a manufacturing environment.

This collaborative work with Dr. Morita at Takachiho University proposes a new framework for a stability-based decision-making process in planning and scheduling, including building a mathematical model and the development of efficient/high-speed methods while considering practical applications. The term "stability" refers to the higher predictability of a released plan/schedule and also signifies the robustness of the plan/schedule against internal and external uncertainties. In the past few years, we have focused on the application of our idea to capacity requirement planning (CRP) in the industry and proposed a robust CRP method that we believe can generate a stable load plan against dynamic changes in a manufacturing environment.

- Robust CRP model and method

- Mathematical model and optimization method of buffer management

- Morita, D. and Suwa, H. (2020) Comprehensive Scheduling Method in Project Management Under Uncertain Environment, 2020 International Symposium on Flexible Automation. doi.org/10.1115/ISFA2020-9617

- Suwa, H. and Morita, D. (2016) Reactive Project Scheduling Method to Enhance Project Progress under Uncertainty, Journal of Advanced Mechanical Design, Systems, and Manufacturing, Vol.10, No.3. doi.org/10.1299/jamdsm.2016jamdsm0051

- Morita D and Suwa H (2015) An Exact Method for Robust Capacity Requirements Planning, International Journal of Automation Technology, Vol.9, No.3. doi.org/10.20965/ijat.2015.p0216

- Suwa H and Morita D (2014) Stability-Based Short-Term Capacity Requirement Planning under Uncertainty, Procedia CIRP, Vol.19, pp.123-128. doi.org/10.1016/j.procir.2014.05.018

People

Supervisor

Haruhiko Suwa

Ph.D. in Systems Engineering

Professor, Manufacturing and Systems Engineering

Dean, Academic Affairs

He was born in 1970 in Kyoto, Japan. He is a professor of Mechanical Engineering within the Faculty of Science and Engineering at Setsunan University. He received his B.Eng., M.Eng. and Ph.D. degrees from Kobe University in 1992, 1994 and 1997. His research areas cover systems engineering, manufacturing engineering, and industrial engineering. His current research interests include green manufacturing, advanced scheduling, decision-making support systems, and project management. He was awarded the Best Presentation Award from the Institute of Electrical Engineers of Japan in 2003 and the Academic Award from the Scheduling Society of Japan. He was a visiting scientist at the Lab for Manufacturing and Productivity at Massachusetts Institute of Technology from September 2012 to August 2013 and July 2014.

Research Staff

- Ryo YONEMOTO: Ph.D., Technical Instructor

- Kazuki SHIMOMOTO: Technical Instructor

Graduate student researchers 2023

- Oda, Kazuya: Ph.D. Candidate

- Shimizu, Haruto: Master's student

- Fujii, Taketo : Master's student

Senior students 2023

- Iba, Tenta

- Iwamoto, Ryoji

- Kanayama, Sohta

- Nakatani, Sawatsugu

- Nakanishi, Yusuke

- Nakamura, Masaki

- Banba, Hayato

- Higashimoto, Shota

- Higashimoto, Shotaro

- Fujikawa, Ryuta

Research Collaborators

- Morita, Daisuke: Ph.D., Assistant Professor, Osaka Metropolitan University

- Samukawa, Tetsuo: Ph.D., Assistant Professor, Setsunan University

Contact

Address

Department of Mechanical Engineering

Faculty of Science and Engineering

17-8 Ikedanaka-machi Neyagawa Osaka 5728508 Japan

Phone/Fax: +81-72-839-9309

Questions, comments and paper requests are directed to suwa[at]mec.setsunan.ac.jp